£2.50 including postage from Hong Kong. They must be rubbish.

I've ordered a couple anyway ...

The float switches look a bit large, but I'll have a poke around for others. Thanks for the links.

Just an update on this.

The cheap pumps arrived from HK a few days ago and I got round to testing them and also the one I got from Hunter's.

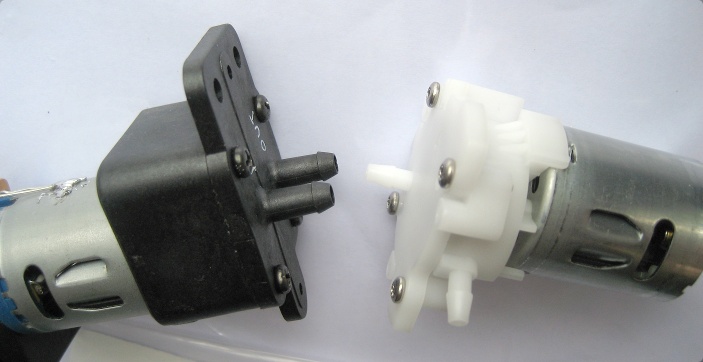

This is the two types:

The one on the left is the Hunter unit in black, on the right in white is one of the Hong Kong jobs.

Clearly the pump casings are different, but both are gear pumps. The connections on the Hunter are larger, about 4mm against 3 on the HKs.

The motor casings are similar enough to probably be the same make, but there are other differences. The HK has a metal end plate, the Hunter is plastic, and the windings on the Hunter's armature are visibly finer than the HKs' which fits with the Hunter being rated 6...12V and the HKs 3...9V.

I tested the units by making them pump water from a bowl into a measuring jug. I used a small, variable voltage power pack to drive them.

I used the 12V setting for the Hunter. It drew about 1.2A and moved 600ml in 30 seconds.

I used the 9V setting for the two HKs. They drew about 2.2A and 2.4A and moved about 380ml and 480ml in 30 seconds respectively. BUT, my little PSU is only rated for 1.2A, so I reran one test to measure the motor Volts instead of Amps and it was only about 3V. Presumably if given the full 9V they would perform better, but also draw more current.

Since my boat has a 12V system I had thought that if these cheapies were OK I could drop the volts using a regulator or even a resistor, but that was predicated on an Amp or so of current. If we're looking at maybe 3A that becomes more of a job and the cost will trade off.

I'm also conscious of purpose. Worst case (nearly) is the boat is damaged, disabled and leaking in the middle of a lake. The bilge pumps need to run until rescued and the difference between 2A and 6A on battery life could be 'the difference'. So I've decided to get a second Hunter unit.

The HK pumps would probably be fine for something less vital - working fire monitors or thrusters maybe. I don't need such things at present, but unfortunately posting them in the UK would cost almost what I paid to get them from HK, so instead of trying to move them on they will go in the future ref box for now.

I couldn't find a float switch that I thought would be suitable, mainly for reasons of space and control of the switching level, so I've also ordered a second Hunter level switch.