OK, so, after too much timke, some updates:

I have the radio gear installed, the servo brackets have been made, bolted through wooden laminated "plates" which are epoxied onto the radio box base. These will be easy to get the servo's out complete with brackets for easy changes.

Some pictures:

Here is the throttle linkage at the engine end. The carb has an accelerator pump so it will be interesting to see how the engine performs when the throttle is opened quickly.

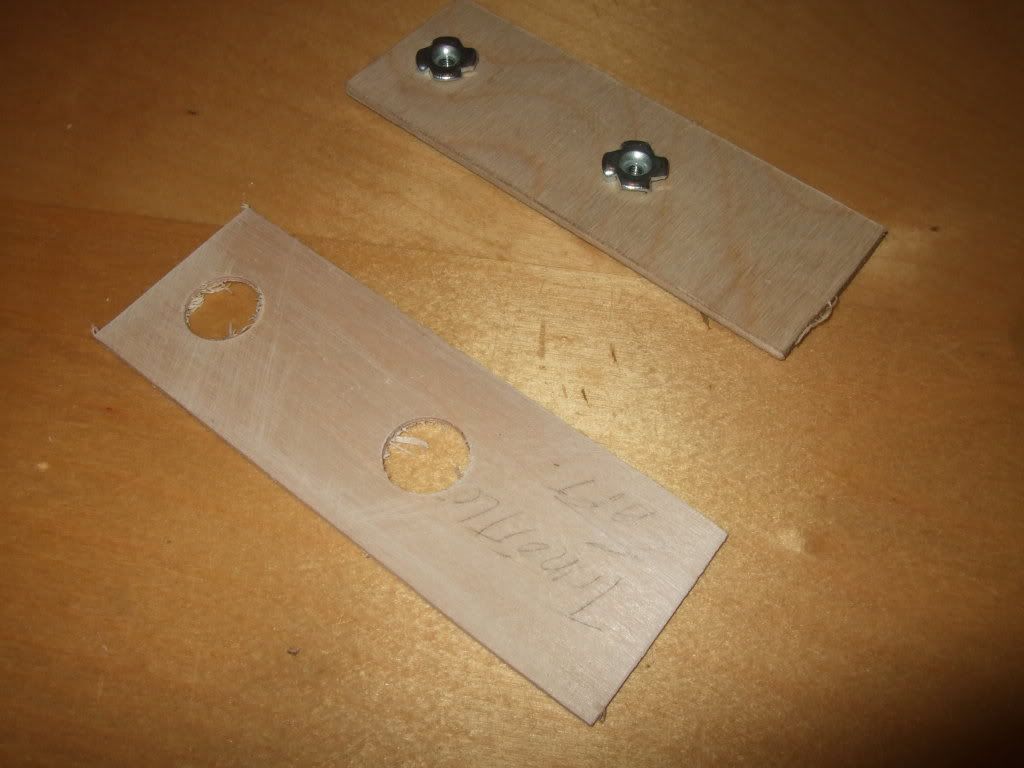

Here is one of the servo plates. These are laminated ply, the captive nuts being pulled into the top sheet, then the bottom sheet being laminated onto it, the whole thing then gets epoxied to the radio box bottom.

The radio box. You can see how easy it is to remove servos.

This final shot showing the rudder ball joint.

I used carbon fibre tubes as you can see for the linkages, they are light and strong. Ferrules of brass tube to prevent the carbon rod splitting (Thanks Ian for the advice).

Engine is mounted, I made some spacers to take up the slaclk fomr the new riubbers, I have changed all bolts and nuts on the model to ensure everything is metric, this resulted in some slack on the engine mounts between rails and the rubbers as the metric rubbers I used are slightly shorter, some spacers made from 3mm aluminum sorted that out nicely.

So all that remains is:

Fit the final top deck where the hatches go, fuel tank in, sand it all down, do any final filling, epoxy the whole thing, then paint, fit out and test. The engine in the pictures is still stock at the moment so that will be ported during the Christmas break with luck. If anyone is interested I'll post some pics of the engine butchery!!

Have a Happy Christmas and a great New Year.

Glenn

Author

Topic: Whiplash Hydro Build (Read 97713 times)

Author

Topic: Whiplash Hydro Build (Read 97713 times)