I thought I'd post a quick (and late night!) progress report on the mend. Thanks to all for the comments and advice. I did consider everything you all said, and in the end I did the following -

I raised the broken seam in the foredeck again with gentle application of a hairdryer (as the sun chose not to shine just when I needed it

). I then applied superglue to the raised edges and as far into the joints as I could. I then pressed the section back into place.

Once I had peeled my thumbs off the deck without losing too much skin, I sanded the foredeck to remove the last vestige of a ridge around the mend and the stain of the superglue. I then coated the deck (and the inside of the boat) in epoxy to stabilise everything. Once this had cured, I sanded that to give a key and started applying varnish. Here is the boat after a couple of coats.

Of course, the glare has hidden the bit that failed before so you'll have to take my word it looks as smooth as the rest.

I haven't "stress tested" the mend by leaving it in the sun for a while, but I will do that once I have finished the varnishing. Better it fails then than on the maiden voyage (fingers crossed smiley here!).

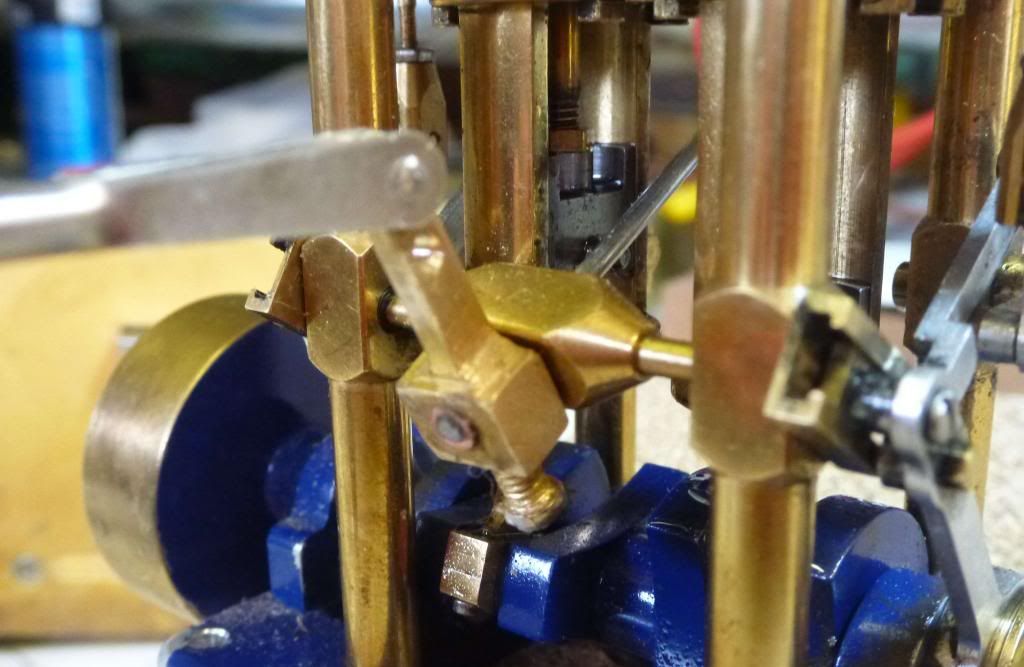

I have also fitted my electrical plug pin, otherwise known as the forward/reverse lever, to the engine. Here it is.

A piece of 1/8" copper tube fitted in the pin hole just fine, and a piece of servo connecting rod (that you get when you buy those clevis things) was just the right size to go through the connector on the engine and the inside diameter of the copper tube. Pure luck!

I glued the whole lot in place in the pin/lever and did the wire clamping screw up really tight as extra insurance.

I have also started insulating my steam pipes. Here they are with the string added. Top right is a test piece with some household filler added as a coating, as recommended by Jerry - I think I might have overdone the thickness, but I'll see how the real ones turn out as I do them - I can always sand them down a bit if they look a bit too chunky. (Jerry - I think you said you painted yours as well - what paint did you use?)

That's where we are at the moment. A couple more coats of varnish should see the end of that then some paint on the hull. Reassemble the steam plant, test run it, install it, test run the whole thing a couple of times, maiden voyage and Bob's your uncle! Next Tuesday then

. OK, maybe the one after that.

Greg

Author

Topic: Solent steam launch build log (Read 51258 times)

Author

Topic: Solent steam launch build log (Read 51258 times)