With Wicksteed approaching, I am trying to mix research with getting M19 finished.

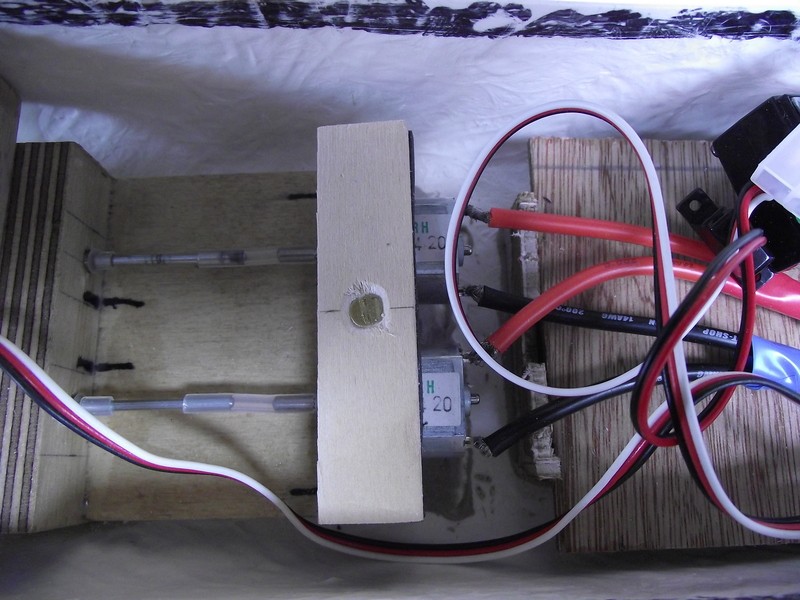

The motors shafts and props were installed. A piece of wood backed with foam tape was screwed across the motors copying the principle offered in the kit. Trying to keep weight down and low has spread gubbins right through the hull, but it is better than her capsizing

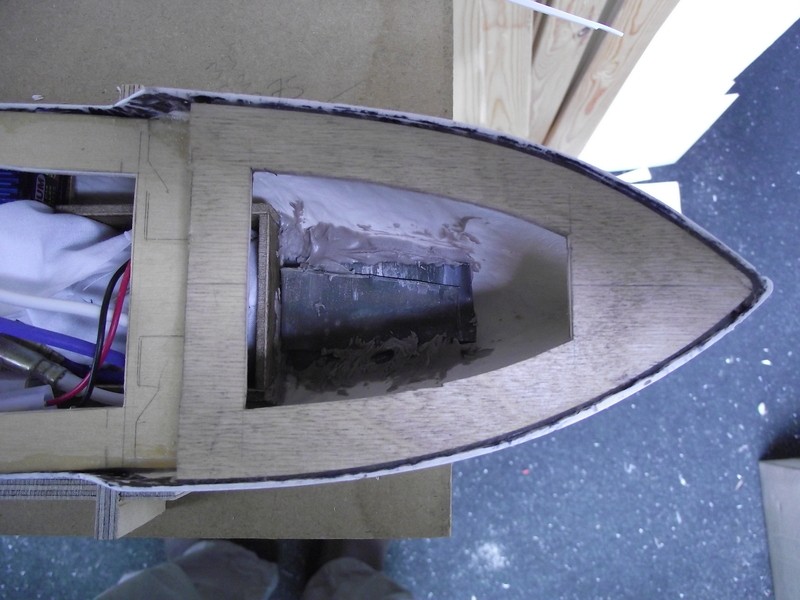

I looked at doing the deckwales using styrene strip but could not see how to keep the hull edge symetrical so cut out a one piece deckwale and stretcher from 3mm ply leaving large holes to access the innards. It was stuck in place with Epoxy, P38 and a bit of superglue.

The same was done for the forecastle. After this was fitted, the bath test was done. She was powered up and I found to my delight that Deans had provided handed propellers explaining why I could not get her to sail the good sea Bathtime without trying to turn around. Ballasting was done with lead flashing.

I duly worked out which prop was which, refitted them and then resoldered the wires on one motor the other way around.

Bath test 2 was a success with good speed and a good strong 'Bonk' when she hit the foot end of the bath

Images shows the Battery in sheath to help pull it out of the bows withut tugging the leads about, Podium ESC, (which is really for a car but I am sure the ABS will not be a problem and may even help when sailing around corners), Planet RX on the other side powered through the ESC (Thankyou for your assistance teaching me this fact).

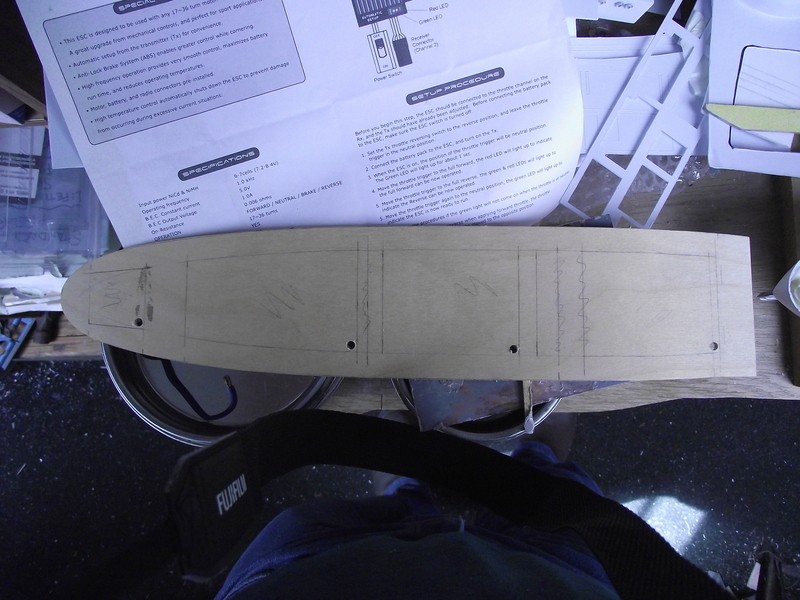

A couple photos of the Foc'sle deck marked for where the fittings will go.

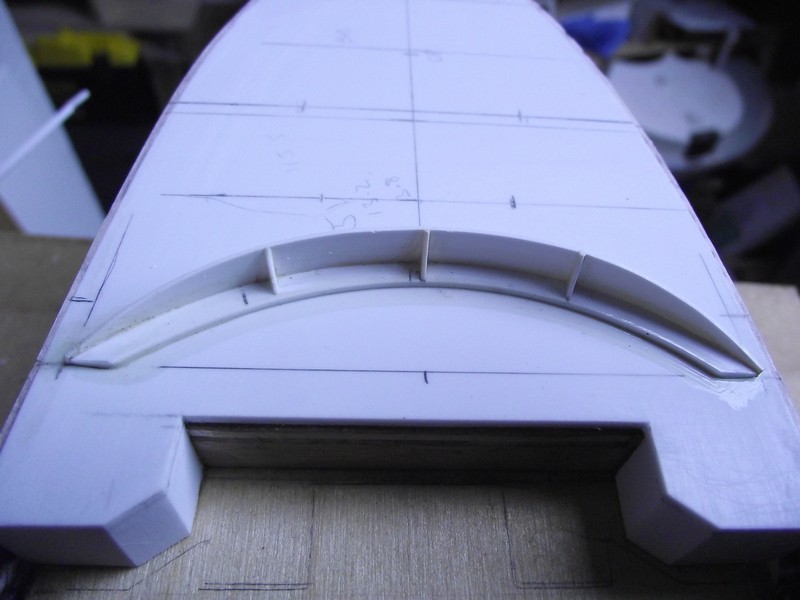

These include an array of vents (see below) as well as anchor handling equipment. The breakwater was fitted at this point. The curved base came straight from the kit while the actual breakwater was made a new using the kit part as a template (original was too short).

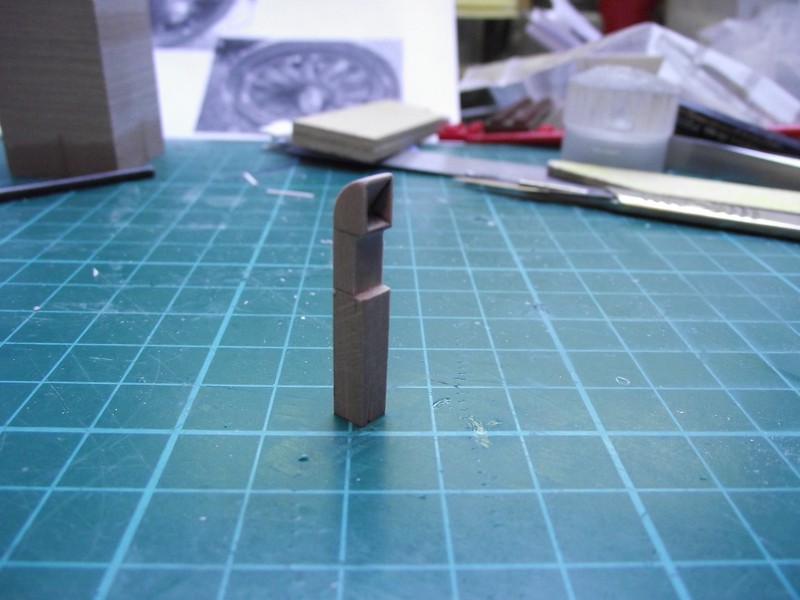

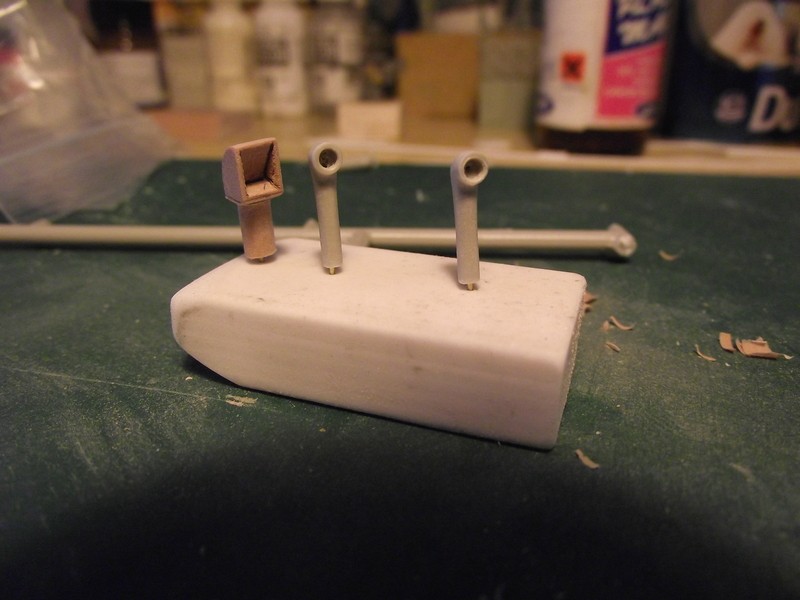

We have discussed recently on how ships of a certain class can differ in detail, and boy does M19 differ! I was cleaning up vents to fit to the foc'sle and then though to look at a good image of M19 in the 'Buxton Bible'. Here I found no fewer then three types, maybe four, of vent. She has a large cowl vent, two small ones and an interesting squared cowl vent. Assuming there was still a single mushroom vent fitted there, I made them.

The above vent was made from chemiwood and is as high as the small cowl vents.

The two small cowl vents were made from pieces of plastic kit sprue by cutting the corner sections off, shaping and drilling the ends of the cowls.

The large one is a spare one ordered from J R Haynes.

Altogether they make the bows look like an architectural salvage yard, which is quite pleasing

Author

Topic: Small Monitor M19 (Read 13832 times)

Author

Topic: Small Monitor M19 (Read 13832 times)