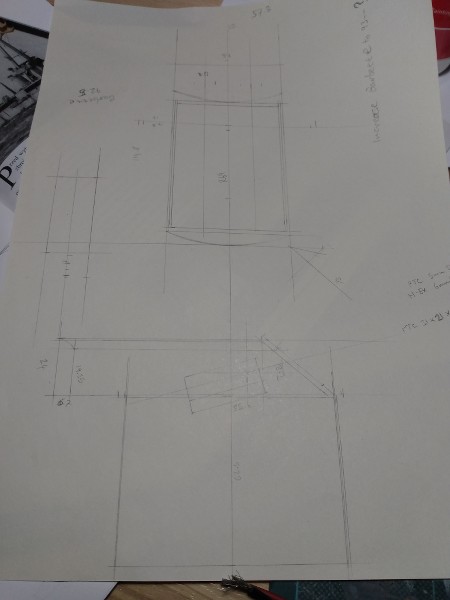

I have begun to work out the turret design and internal layout.

The turret is quite narrow, despite it's barbette diameter, giving me a maximum of 56mm internal width for the two thermistors and heat exchangers.

Having drawn up a basic plan, I then bought some Bristol board 1mm thick to build a mock turret from.

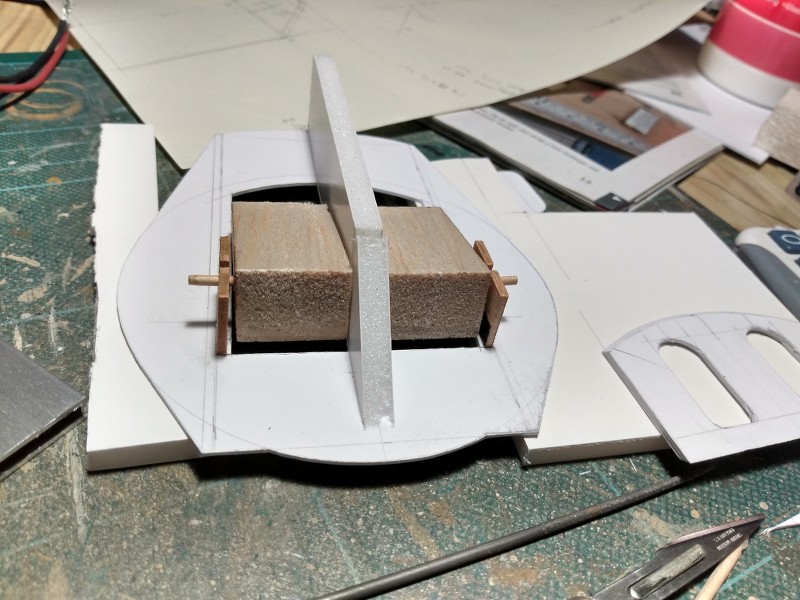

So far, I have cut the floor, the front plate, and have cut a central spine from 5mm foam core.

Two balsa blocks were cut to mock up the thermistor/heat exchangers with pivots from cocktail stick! (It's all Blue Peter here you know!!!)

Issues I have found so far is that, having moved the exchangers forward by 5mm to give the leads more space, I cannot insert them from above once the front plate has been fixed in place. I want the front plate to support the sides and central spine to make the turret 'box' rigid for any stresses caused by the sprung injectors pushing against the cams. This means it cannot be part of the roof.

Therefore I think I can modify the central spine to have a removable section above the pivot big enough to slide the exchangers down and in.

Now I have the thermistors I can see if they char ply at 230 degrees and work from there.

Author

Topic: HMS Raglan in 1:96th (Read 7565 times)

Author

Topic: HMS Raglan in 1:96th (Read 7565 times)