Hi Ian

I do have a set of HSS tools, but I don't have a grinder that I've always thought I needed to sharpen them. So I must admit that I like the replaceable carbide tip tools as I can just replace the tip when I start something that needs a good sharp tool. I'll have a go at sharpening the HSS tools, I'm guessing that you mean the shapes of the HSS tools may be more suited to brass / aluminium (rather than the carbide 'points')..?

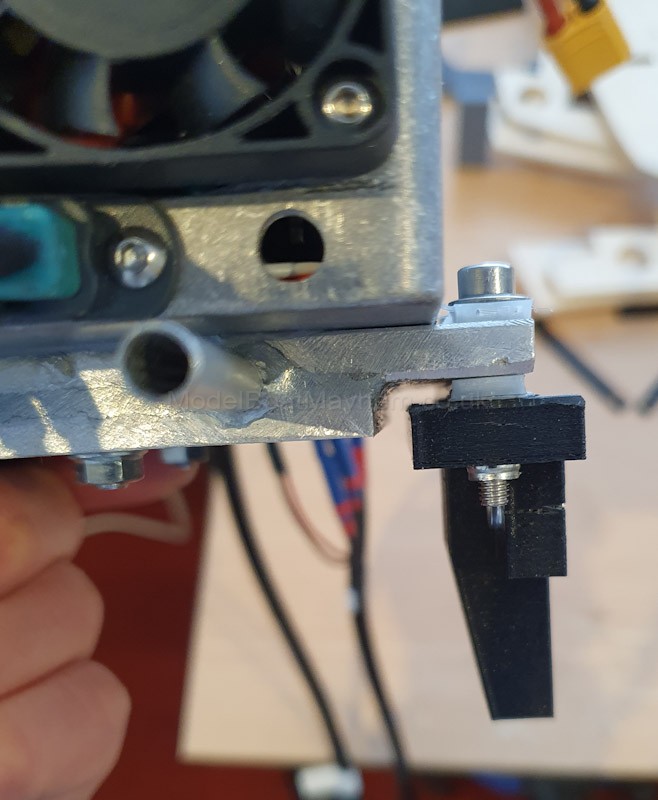

In other news... I've got the ESC Case mounts fully sorted. I used the 3D printer and some flexible TPU filament to create some mount inserts that keep the case 100% isolated from the mounting bolts and the hull mount. Might be overkill and a waste of time, but I'll know that I tried. (To avoid any sounds from the ESCs being passed to the hull...)

Also some progress on the dock lights to report. I reduced the diameter of the 'reflectors' a shade in the lathe, bit precarious, but got there in the end.

This pic shows the original reflector, then cut down, then in the dock light

And the pair installed

Need to get them powered up to see if I'm on the right track. I call them reflectors, but there's no silvering and they're solid plastic, so by changing the shape I may have altered their characteristics, I'm thinking of silver painting the outer face and seeing what happens.

Very pleased to have made some progress on the actual hull, rather than just fittings..!! I'm two years into this build, so about time I reckon.

Here's the Stringers ready to shape and install. Transom / Stern assembly in the background being glued.

And that stern assembly in place on the keel, just dry fit.

And this stringers cut to fit the frames

Again still dry fit, but nice and tight, some shaping left to do, and some holes to drill. The 'underside' of the stringers is deliberately protruding beyond the frames so I can plane them flush and plank over them once bonded in. The stringers not part of the Amati design, just my attempt to add some stiffness. They are 10mm apart so they can act as strengthening for the prop tubes, P brackets and rudders. And provide some good alignment for that hardware.

P Brackets will need some sort of padded insert, and rudder tubes will need boring out a shade.

But finally feeling like a model boat project rather than a model engineering exercise... Flat sections of the hull are bases for the motor mounts. And some comparison with my 86cm 1/10 Aquarama...

Finally. I have an order in for 100 Mahogany and 80 Lime planks... Hopefully picking them up next week. 2m lengths.

Best regards to all.

David.

Author

Topic: 1/5 Riva Aquarama... (Read 142608 times)

Author

Topic: 1/5 Riva Aquarama... (Read 142608 times)