I have not kept up here for a while,

my bad...

Apologies for the pictures being links but here are some from the engine build:

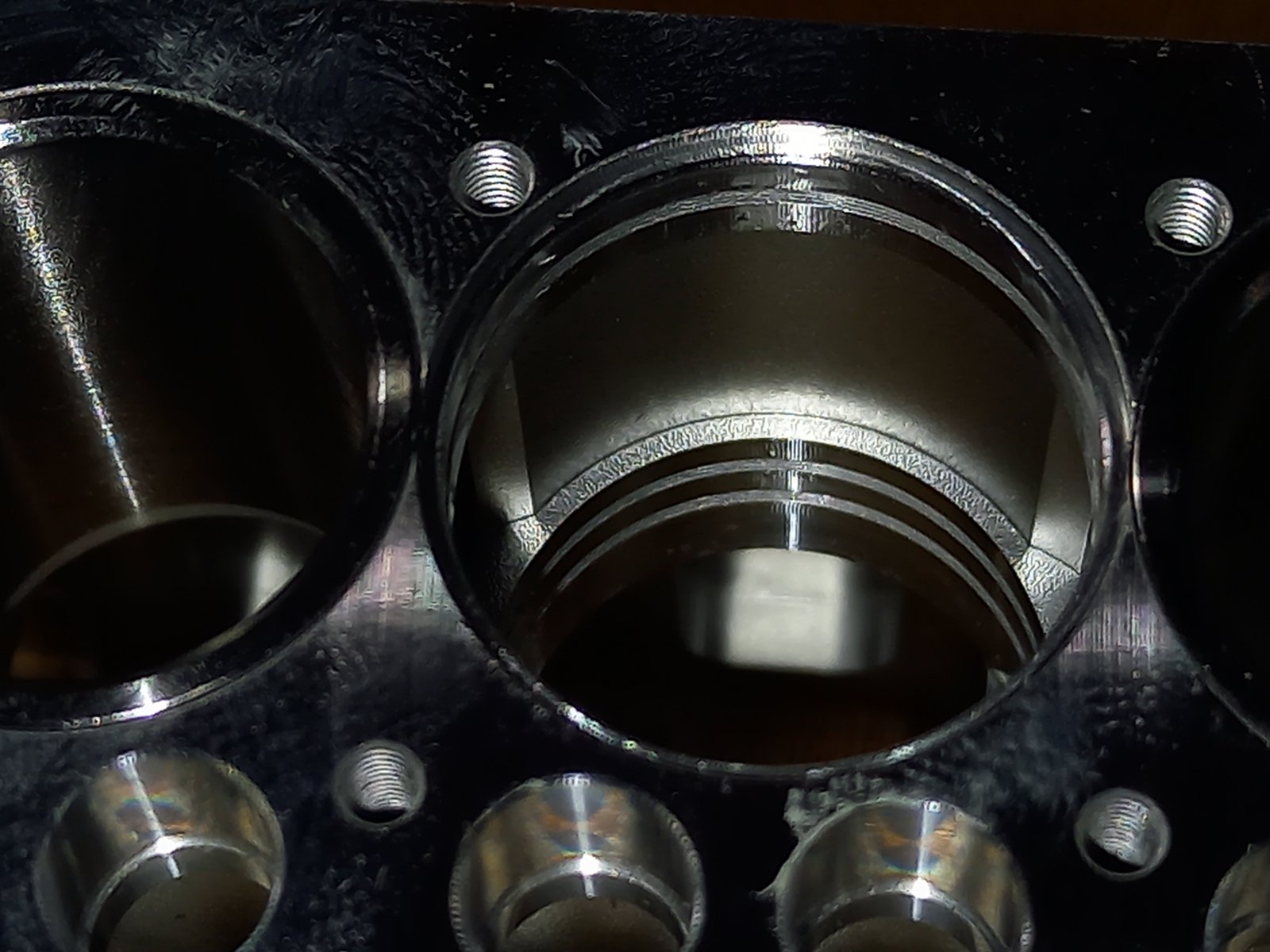

First step in the build was to fit the liners into the cylinder block. In order to do that, for each cylinder three O-rings sealing off the cooling water jacket needed to be installed. These things are pretty filigrane (string diameter about 0,7 mm), and the bores are only about 17 or 18 mm.

I could barely get my index finger into the bore whatsoever, so it was a lot of fussing about with one pinky and a toothpick to manipulate the rings in their slots.

A bit of grease on the liner serves to allow the liner to be slid into the bore, and care must be taken that the bevelled edge passes the rings properly, or liner and block will act like a scissors and cut the rings.

There are 12 O-rings needed, and 13 in the kit, so you can only make ONE mistake...

Next step was the installation of crankshaft (of which I did not really take pics, sorry) but it was pretty straightforward: a ball bearing on the distribution side of the crankshaft, and since clearances are extremely tight, a bit of fiddling is needed to jiggle the crank into position.

About 5 mm before the crank is in position, the two halves of the brass support bearing heed to be placed, and although an easy understandable operation, due to the tight clearances and fit, this is a bit of a hassle. Once in place, the crank can be pushed home, and a single M3 bolt locks the support bearing assembly against rotation.

In my case, the crank turned over extremely smooth, no fuss, no fiddling, no search for undesirable friction.

After that, time to install camshaft and distribution.

This part is really beautifully made, with proper keyways and keys, all extremely miniature and ultra-realistic.

(the hole in the large gear has a reason: Once fitted, it is impossible to pull the gear off due to lack of purchase. The bearing of the camshaft is locked in place with two screws, so the hole serves to remove these screws, in order to pull camshaft and gear together. There are no timing marks, the keys serve that function)

This was the first point where I encountered poor fit: the keys were ever so slightly too large and I had to file them down a touch with a needle file, which is not that easy to do given that the key was about 1,5 x 1,5 x 5 mm. How do you hold that in a vise?

(you don't... between the fingertips and accept that you're going to loose a bit of epidermis on the fingertips... :p )

Then the conrods and pistons need to be joined. Another not too impressive part of the engine: According to the description, the bosses in the piston should be a bit different in diameter, with one slide fit and one press fit. The idea is to fit the gudgeon pin into the slide fit, position the small end, then carefully push the gudgeon pin home, with the addition of a bit "anaerobic 242/271" (more commonly known as "loctite"

).

Only one piston showed these characteristics, the other three pistons had no noticable difference in fit and were slide fits.

One of the gudgeon pins even was a tiny bit too large and I had to carefully grind that one down ever so slightly.

So I fitted all four gudgeon pins with loctite, something I raise my eyebrows over to be totally honest.

There was no space to place Teflon pads like in most normal model engines.

Oh well, nothing I can do about that...

The piston rings are pretty filigrane too, and I was worried that fitting the 2nd ring (which has to pass the first ring) would be problematic, but I was surprised how easy each ring (all 8 of them) went in their allocated slots.

Next step, the pistons need to be placed in the liners and the conrods hooked up to the crankpins.

First a drop of oil in the liner, on the piston, on the small end and the crankpin.

Next the big end bearing is opened. Care to be taken that only one rod is opened at a time so as to not mix rods and caps, because the rod and cap are paired. The caps also should be fitted in the same position as they came off, there is a tiny notch indicating that position.

The big end bearing has an oiler hole in the rod, the oiler hole should be on the side of the oil gallery.

When fitting the piston into the cylinder, the liner has a tiny bevel topside, the first ring easily slides in with a bit of pushing the ring in with a toothpick.

The pitfall is getting the top ring in: It just so happens that at the same point where the top ring needs to pass the top of the liner, also the conrod meets the crankwebs at the tiniest bit of misalignment. If you don't catch this interference, there is a risk of damage to the bigend bore and the landing face of the big end cap when you push too hard in an effort to get that darn ring (which is NOT the cause of resistance) into the liner.

REAL care must be taken that the rod is hanging free between the webs instead of interfering with them.

Once that hurdle is passed, pushing everything home and fitting the bearing cap is straightforward.

Now immediately it becomes clear how much friction piston rings generate: that smoothly turning crank became increasingly resistive with every piston installed.

That should cure itself during break-in I guess.

Fitting the flywheel casing (which also holds the pre-fitted DE bearing of the crankshaft, is nothing worth mentioning, and ditto the fitting of the largely pre-assembled head. I am a bit sceptical about the non-metallic head gasket, but it is what it is, more about that later.

Fitting the cam followers, pushrods and rocker arms also is very uneventful, but one thing that stood out: the designer took a shortcut for the cups holding the pushrods. Normally, pushrods are fitted with hemisphere ends, and rest in properly fitting cups. On this engine, the rods are rounded, and the cups are.... the internal hex holes of Allen head bolts...

It will probably work just fine, but hey...???

The downside of this is that valve clearance probably will need frequent adjustment initially because of the rod-ends mating with the Allen heads, working their way in a bit, and that's the thing: adjustment needs to be done with needle nose pliers acting on those cups, there are no slots in the threaded ends of the adjusters. Oh well, that 1000 Euro price HAS to come from somewhere, right?

Installing the starting gear is a real PITA, because the one way bearing in the main starter wheel is keyed to the shaft and a fairly tight fit.

Pushing this home while only being able to turn one way to align the slot, while at the same time trying to make the teeth of the intermediate gear mesh, well, it took me several hours before it suddenly and without identifiable reason clicked into place...

And that's where I have landed now...

<iframe width="560" height="315" src="

https://www.youtube.com/embed/h7xRAO7QpUY?si=98UIDTsX_pkxOdg6" title="YouTube video player" frameborder="0" allow="accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture; web-share" referrerpolicy="strict-origin-when-cross-origin" allowfullscreen></iframe>

https://www.youtube.com/watch?v=h7xRAO7QpUY Author

Topic: Gasoline powered Tugboat (Read 106143 times)

Author

Topic: Gasoline powered Tugboat (Read 106143 times)