Right, I'm back - work been manic recently, camera been playing up and 3 kids, so not posted anything for a little while. Sorry to any watchers who've missed the updates.

Good news - for me, the sponsons are done, in fact, the hull is done, only needs the deck on.

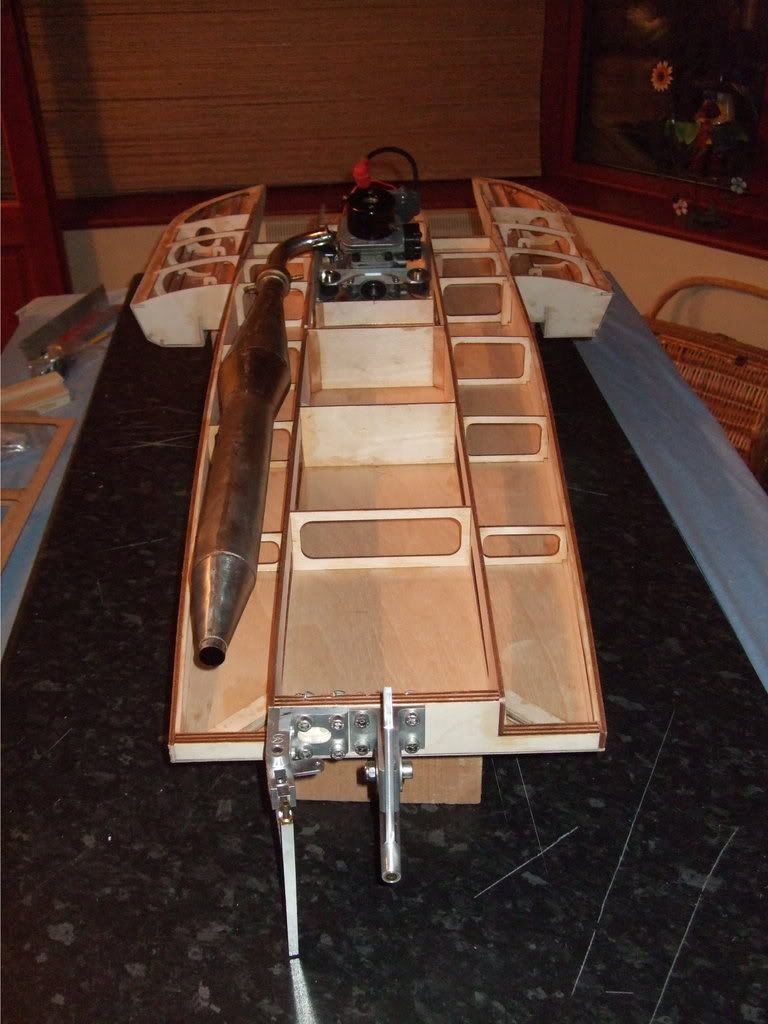

The hull from the rear.

The hull from the front.

As you can see, the rudder bracket and drive strut are fitted, the rudder is awaiting arrival of a new rudder bearing block witht he control horn on the right side instead of the left, want the rudder on a "pull to turn right" set up, the control rod is around 400mm for this thing. The rod itself is carbon fibre, got a test sample curing now with 3mm studs bonded in, wnat to ensure my servos are not going to be able to pull the studs out of the carbon fibre tube, so calculated that on 15mm servo horn, the S3305 servo with torque of 8.9Kg/cm, will be capable of exerting a linear force not exceeding 6.675Kg.

So I am going to clamp my test piece in the vice and try to hang 7Kg off it, if it's a success then I have my control rod sorted! Brutal but effective.

I now have an engine ready for this boat too, I had a new Zenoah PUM26 which was un run, I recently completed some porting alteration work, along with piston lightening, etc etc, the engine was test run last week in my Panther and ran very well. Good spread of power with a fairly healthy top end, got over half an hour running on it so it is run in and ready to start to increase run times and speed. This will happen in the Whiplash. I also picked up a CS23a Prestwich tuned pipe for the model - great pipes, plenty of power and very quiet.

So as you see, it's coming together. Next to do is mount the motor properly to the hull, then fit the prop shaft tube.

Here is a sneaky peek at the turn fin - I told you all earlier it is huge!

Hope to get more done this weekend for uploading Sunday.

Glenn

Author

Topic: Whiplash Hydro Build (Read 97749 times)

Author

Topic: Whiplash Hydro Build (Read 97749 times)