Afternoon All..!

A little progress to report, not as much as I'd hoped, but isn't that always the way...

@Ian, all feedback gratefully received, I like being on the forum for that very reason. When I just have myself to discuss best approach to whatever I'm doing, I tend to agree with myself... And that's not always a good thing..!

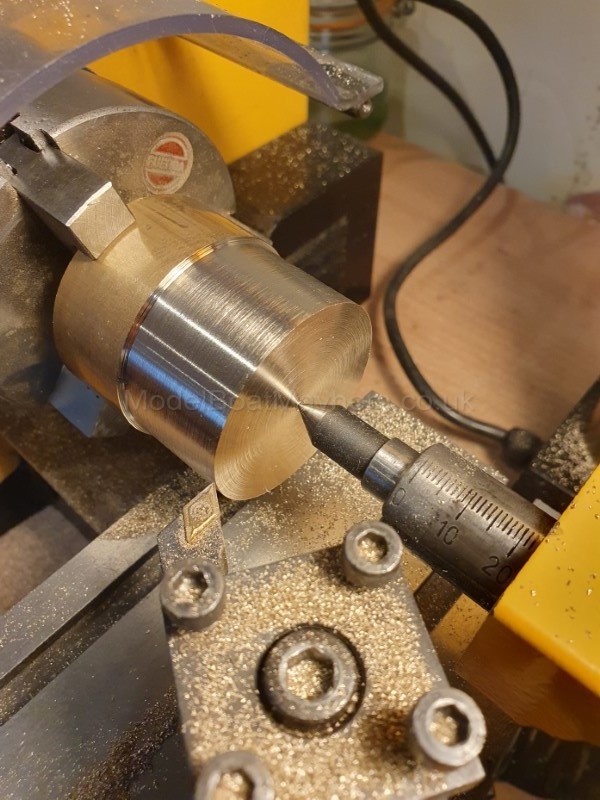

So, here's the 50mm bar with tailstock centre to keep it under control, I don't have a thrust pad... So did take it slowly.

Taken down to 48mm and tested with the guide.

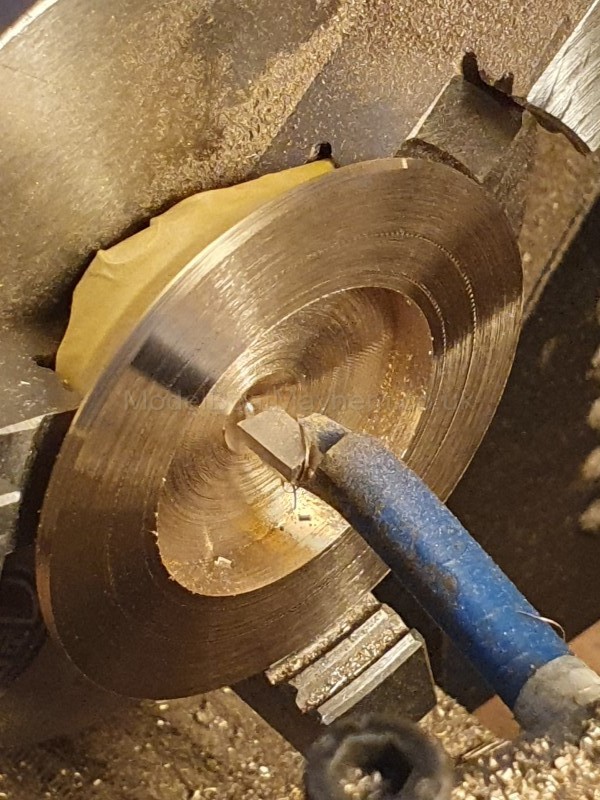

Parted off with a parting tool and hacksaw.

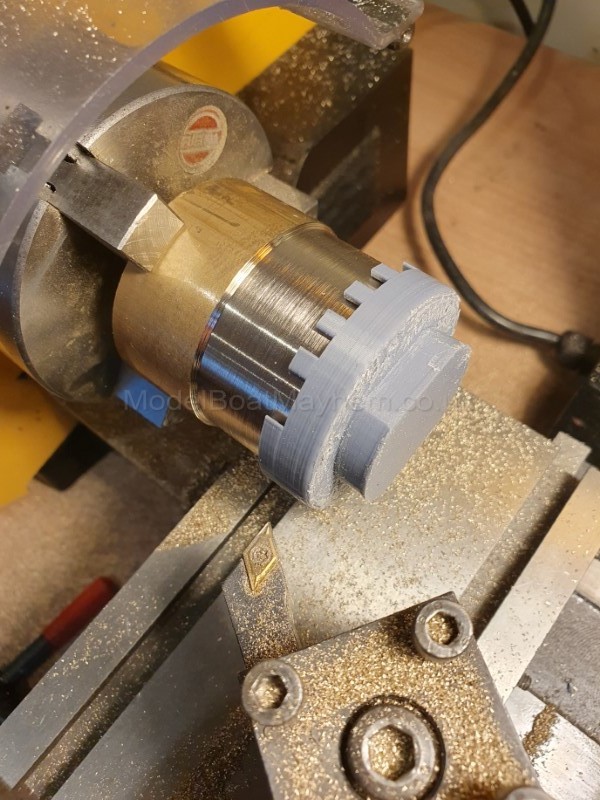

Then the vent reversed (protected with some masking tape), back in the chuck, faced and marked for boring out.

Then drilled to give me a depth to work to, and bored out.

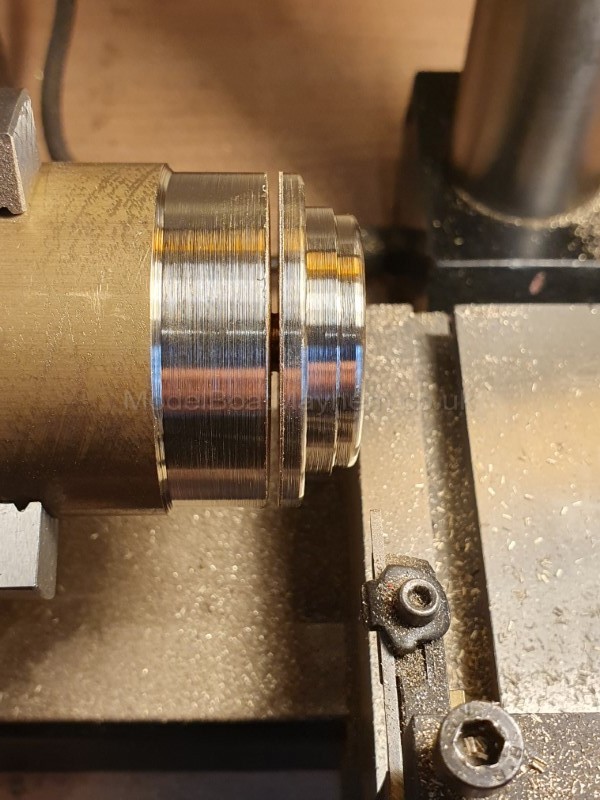

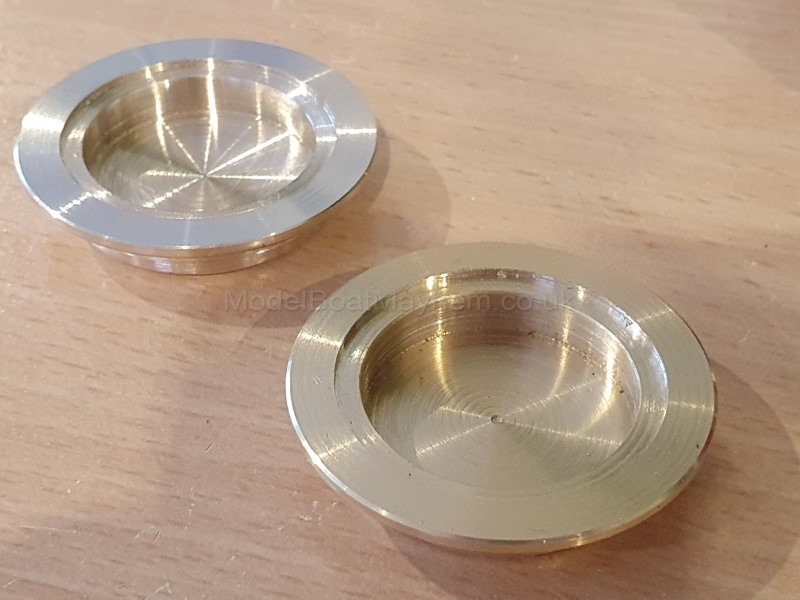

And the result, extra cut on the flange is 1mm deep to take some acetate sheet.

Then into the guides to have the flange mounting holes drilled.

Then countersunk and mounted in the guides with M2 bolts. On the model the bolts will be M1.6.

The flats on the underside of the guides are to help mounting in the mill. Then a 6mm end mill to take out the two edge cuts, and a 4mm to start on the centre cuts.

And that's as far as I've got today... So, two more cuts on that first vent will give me the 'bars' of the vent, probably a bit of filing to round off the edges. I'll post an update when they're both milled.

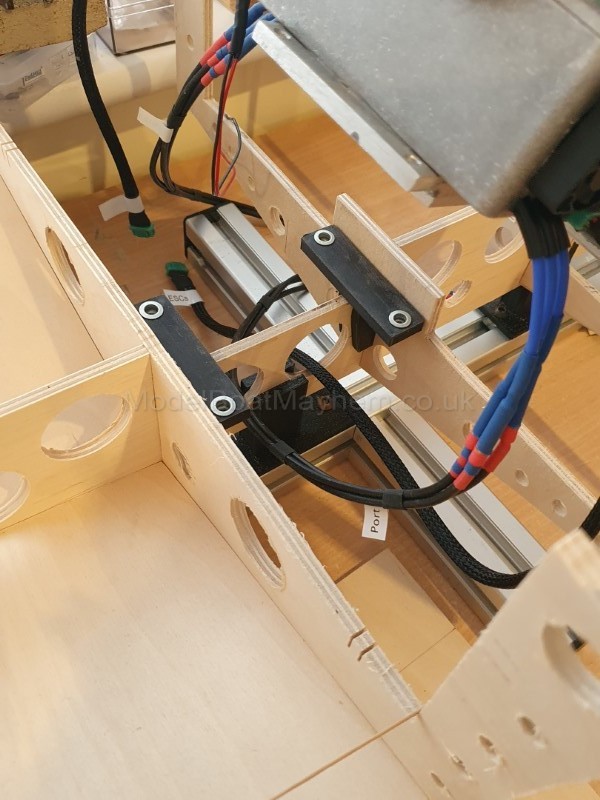

In other news... I produced a few versions of these 3D printed ESC case mounts before getting it right. They sit on the keel and bolt through two of the frames so the ESC case has a firm base. I will be using a thin piece of foam to isolate the case from the mount so no sound vibrations are passed to the hull, or are at least reduced.

And with M4 threaded inserts.

And in place, dry fit at the moment.

That's about it for today...

Very best regards to all.

David.

Author

Topic: 1/5 Riva Aquarama... (Read 150731 times)

Author

Topic: 1/5 Riva Aquarama... (Read 150731 times)