At this point the skeg Iíve been planning may not be the best idea, to make one level with the hull would reduce the rudder size dramatically, obviously there are ways around this, but I donít think many are suitable.

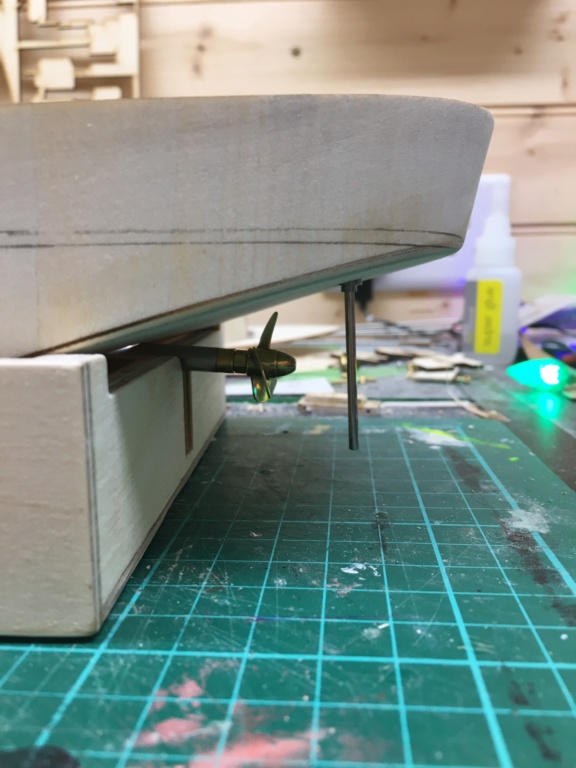

Anyway moving forward while I ponder on skegs, Iíve made up a support bracket for the prop shaft, the original hole is overly large designed for a standard shaft (8mm) I donít tend to use brass shafts anymore simply due to corrosion over long term use, so sticking with my go to stainless shafts being thinner it required a mounting bracket to hold position and angle, this will let me fit a motor at the correct angle.

Now the kit comes with a laser cut motor bracket, but it requires you to cut the shaft ( and they recommended a 100mm shaft ) to allow the motor to be moved in front of the 2nd bulkhead, on top of that they also want you to take the motor spindle out and reverse it, so the motor is backwards.. this I understand the logic, once the decks on you will not be able to remove a motor is mounted the Ďnormalí way, however I donít see the point in 1 cutting a perfectly good shaft down, and 2 swapping the motor about when a different bracket can be made up that can support traditional methods of mounting, not forgetting this kit also provides you with a laser cut mount for a servo... that in my case will not fit due to the servo I brought, but the position on the plan gives you no way to remove the servo at a later date... my plan is to make a mount for both motor and servo together as one unit that can come out through the hatch, and screws vertically into the electronics tray, this will mean that the battery will not sit right in the bow as the plan states so I will make a battery tray to sit over the shaft which my hand can get the battery to sit on ( I did a dry fit to see what I can and canít do) the electronics can then sit either side off the shaft in front of the motor.

Itís an adjustment to build instructions but one I think is better than the half assed method someone came up with for this.

Talking on motors, I had a spare 1500kv outrunner laying about, that was used for a display model, so Iíve removed that motor and swapped it out with an on going project on another boat... that boats motor is one suitable for this model, itís much smaller in size but still above what the kit recommends, itís a 1200kv 85w outrunner (20amp esc) 28mm can size. Again my go to brand overlander, tried tested and never failed! ( these even work in reverse flawlessly) but they are quite expensive In comparison to other motors similar spec.

My next task is to make up a coupling, I have a few spare ones laying about but I think Iíll just make one for purpose, a UJ (Huco) coupling is actully to long to fit with the motor and shaft as is, so not suitable for this model unless I want the motor in the bow!

As you can see from the photo the 25mm prop is perfect size, the photo is deceiving in this case it looks like I can add a 30mm sadly I only have 1mm clearance from the shaft correct position.

The grind continues...

Author

Topic: Chinese mini tug the Q3 kit! (Read 17004 times)

Author

Topic: Chinese mini tug the Q3 kit! (Read 17004 times)